Switchroom description

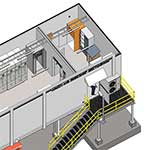

A transportable switchroom is a non-fixed building that contains electrical equipment such as HV (high voltage) switchgear, LV (low voltage) motor control centres, variable speed drives (VSDs), communications equipment and more. Included with switchrooms are the auxiliary equipment necessary for the room's operation - HVAC (heating, ventilation and air conditioning), lighting and small power, fire protection systems and similar. They are typically used in industrial locations, such as mine sites and resource processing facilities.

Transportable switchroom types and sizes

Switchrooms can vary in size depending on a client’s requirements. Larger rooms are designed with transport splits (to fit on multiple trucks) and reconnected on site.

Why transportable switchrooms are useful

Switchrooms provide a clean and controlled environment for electrical switching equipment, which assists with equipment service life and reduces the likelihood of equipment failure. Keys or card access systems can be installed to restrict switchroom access to authorised personnel, limiting exposure to high risk activities such as high voltage switching.

Transportable switchrooms are a cost-effective solution compared to a permanent switchroom built on site, as they are assembled, fitted out and commissioned off-site.

Transportable switchroom design and implementation

General design process

Usually, we start by reviewing our clients’ design criteria and equipment list. Using this as a basis, our clients provides single line drawings and specify the type of switchgear to use. Using this as a basis, we take the client's standards specifications to develop a layout drawing and floor plan. General considerations during design of switchrooms include:

- Compliance to Australian and client standards

- Wind loading

- Access/egress requirements for normal and emergency situations

- Cooling requirements

- Fire detection and suppression, and

- Other requirements as dictated by the client or situation

Quality switchroom design

We often find the best project outcomes result in:

- The client's requirements being met or exceeded whilst ensuring design conformance

- Minimal interfacing issues on site during commissioning

As a result of our experience in this area, we approach our engineering, procurement and construction accordingly.

Poorly designed switchrooms

We normally advise clients that poor designs and implementations occur when switchrooms are designed with no consideration to their surroundings. For example, the orientation of the stairs may be unsuitable, concrete footing heights may be incorrect or the requirements or cable ladders under the switchroom have not been taken into consideration. Such oversights in design (often due to a lack of communication or appropriate budgeting) often cost the client far more in on-site modifications, human resource hours and lost production.

Why Teck Global makes superior transportable switchrooms

At Teck Global, we take transportable switchroom design seriously. From the client's requirements, to the interfacing requirements of the switchroom, to a smooth commissioning process. Furthermore, our local team and presence allows our clients a level of security that other switchroom designers cannot match. We encourage interested parties to get in contact to see how Teck can best suit your needs.

Our services do not end upon delivery of the rooms. We can also offer commissioning assistance on site.